Dr. Valentine Guzman

SPORTS CHIROPRACTIC - About Dr. Guzman

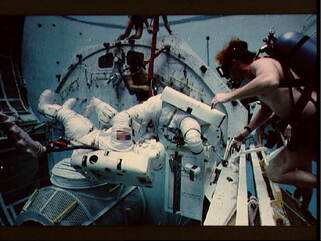

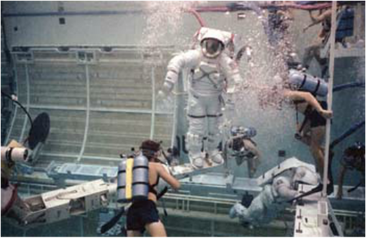

Weightless Environment Training Facility(WETF) Johnson Space Center

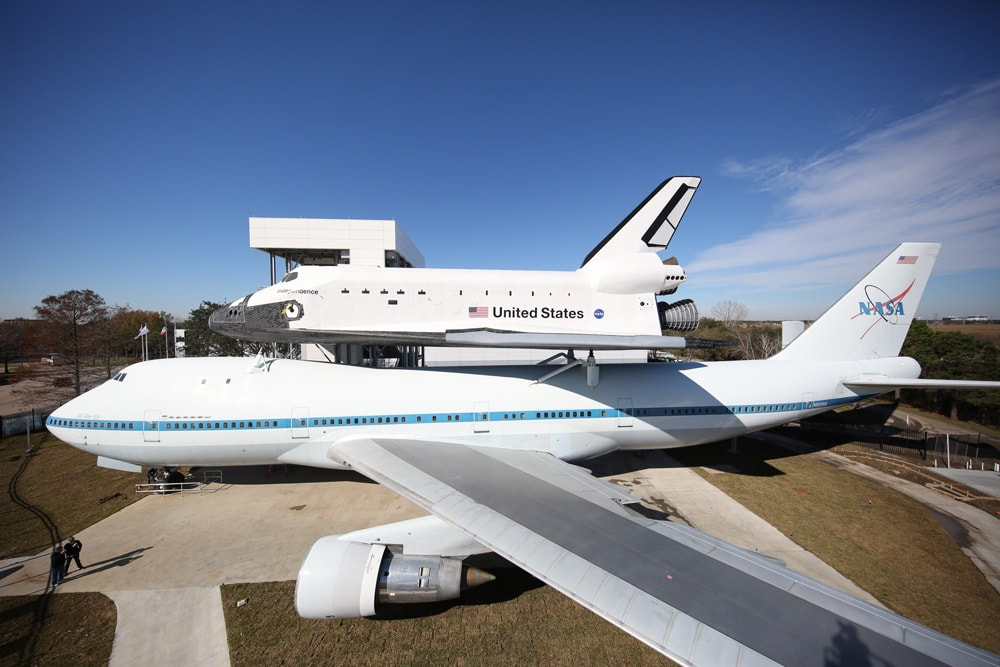

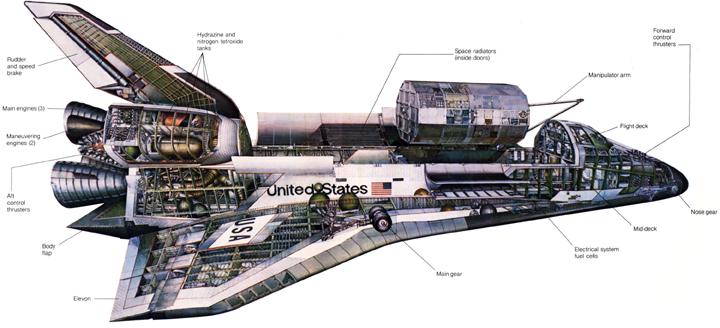

Dr. Guzman's last assignment at Johnson Space Center was in the position of Engineer for the WEFT, a 25' x 72' x 40' swimming pool where astronauts donned their space suits, entered the swimming pool, which had a mock-up of the Space Shuttle Payload bay, and then they designed and practiced their up coming space walks. As part of this assignment, Dr. Guzman was required to maintain his certification as a NASA Safety Diver and participate in weekly astronaut training sessions, space walk(Extra Vehicular Activity(EVA), designing facility communications and data-acquisition systems, operational readiness and test support design activities. This contract engineer position was part of Northrop Aviation - Service and later Dr. Guzman was in the Business Development Team.

Dr. Guzman's last assignment at Johnson Space Center was in the position of Engineer for the WEFT, a 25' x 72' x 40' swimming pool where astronauts donned their space suits, entered the swimming pool, which had a mock-up of the Space Shuttle Payload bay, and then they designed and practiced their up coming space walks. As part of this assignment, Dr. Guzman was required to maintain his certification as a NASA Safety Diver and participate in weekly astronaut training sessions, space walk(Extra Vehicular Activity(EVA), designing facility communications and data-acquisition systems, operational readiness and test support design activities. This contract engineer position was part of Northrop Aviation - Service and later Dr. Guzman was in the Business Development Team.

Johnson Space Center, Weightless Environment

Training Facility(WETF)

Training Facility(WETF)

Shuttle Avionics Integration Laboratory (SAIL) Johnson Space Center

Dr. Guzman was in the position of Quality Engineer responsible for tracking authorized engineering changes to the frame-less Space Shuttle serial number 093, used in flight simulation testing, Space Shuttle Flight software validation. The Space Shuttle serial number 093 has all the wiring, equipment, cockpit configuration, sensor and cable construction of a Space Shuttle but no air frame since it was connected to a Singer Flight Simulation computer, all housed at the John Space Center, Building 16, Shuttle Avionic Integration Laboratory(SAIL). The testing on the software and hardware were performed before the actual Space Shuttle Approach and Landing(ALT) flights were conducted, verifying software operational requirements. This contract engineer position was part of Rockwell International Corp, the builders of the Space Shuttle.

Dr. Guzman was in the position of Quality Engineer responsible for tracking authorized engineering changes to the frame-less Space Shuttle serial number 093, used in flight simulation testing, Space Shuttle Flight software validation. The Space Shuttle serial number 093 has all the wiring, equipment, cockpit configuration, sensor and cable construction of a Space Shuttle but no air frame since it was connected to a Singer Flight Simulation computer, all housed at the John Space Center, Building 16, Shuttle Avionic Integration Laboratory(SAIL). The testing on the software and hardware were performed before the actual Space Shuttle Approach and Landing(ALT) flights were conducted, verifying software operational requirements. This contract engineer position was part of Rockwell International Corp, the builders of the Space Shuttle.

Rockwell International, Project Engineer Office, Johnson Space Center

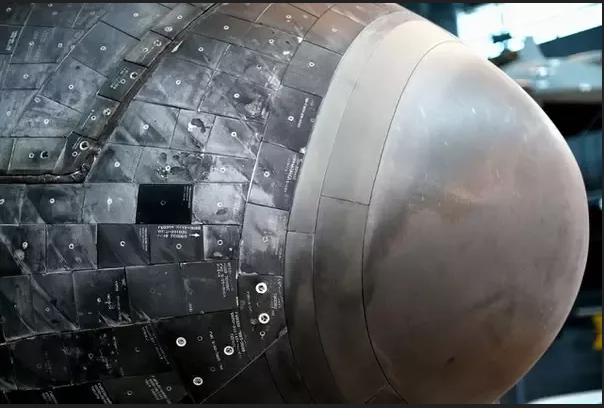

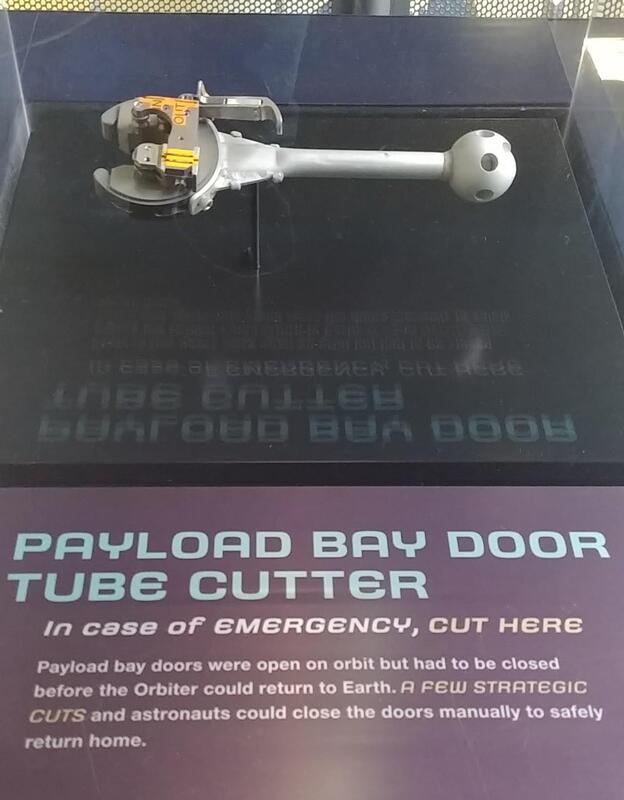

Dr. Guzman was in the position of Group Leader, Project Engineer, where the department was responsible for preparation, monitoring and coordination of non-destructive testing for Space Shuttle components at Johnson Space Center facilities such as the Plasma Arc Facility for thermal testing the Space Shuttle heat tiles and RCC nose cone, Air Loads Testing for wing components, and coordination special projects such as the design of the hand tools used for closing the Space Shuttle Payload doors if failure should occur.

Dr. Guzman was in the position of Group Leader, Project Engineer, where the department was responsible for preparation, monitoring and coordination of non-destructive testing for Space Shuttle components at Johnson Space Center facilities such as the Plasma Arc Facility for thermal testing the Space Shuttle heat tiles and RCC nose cone, Air Loads Testing for wing components, and coordination special projects such as the design of the hand tools used for closing the Space Shuttle Payload doors if failure should occur.

General Electric, Space Division, Manufacturing Engineer, Johnson Space Center

Dr. Guzman was in the position of Manufacturing Engineer, responsible for supporting the fabrication of NASA related articles, such as those for related to the the Space Shuttle and the European Space Lab. These General Electric fabrication efforts covered the machine shop, the electronics fabrication shop, the astronaut Garment Fabrication shop, and vibrations laboratory. Dr. Guzman was the lead engineer for the fabrication of the Space Shuttle Environmental Cart, which connected to the Space Shuttle Crew Cabin Simulator, making the first heat, air, temperature studies of the Space Shuttle Crew Cabin.

Dr. Guzman was in the position of Manufacturing Engineer, responsible for supporting the fabrication of NASA related articles, such as those for related to the the Space Shuttle and the European Space Lab. These General Electric fabrication efforts covered the machine shop, the electronics fabrication shop, the astronaut Garment Fabrication shop, and vibrations laboratory. Dr. Guzman was the lead engineer for the fabrication of the Space Shuttle Environmental Cart, which connected to the Space Shuttle Crew Cabin Simulator, making the first heat, air, temperature studies of the Space Shuttle Crew Cabin.

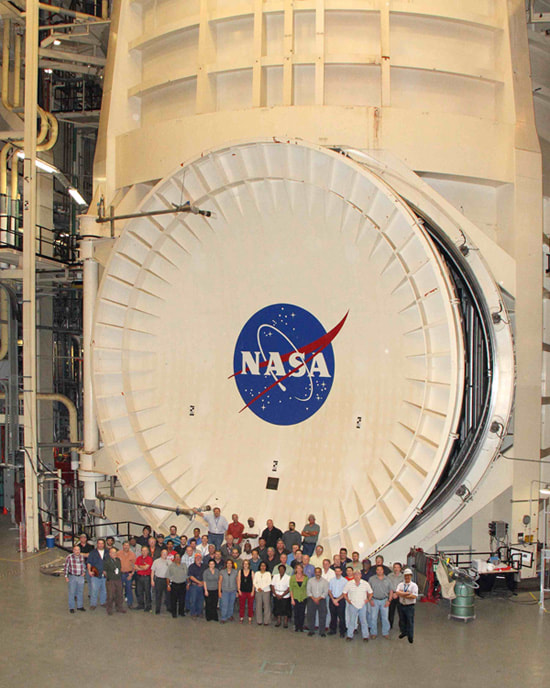

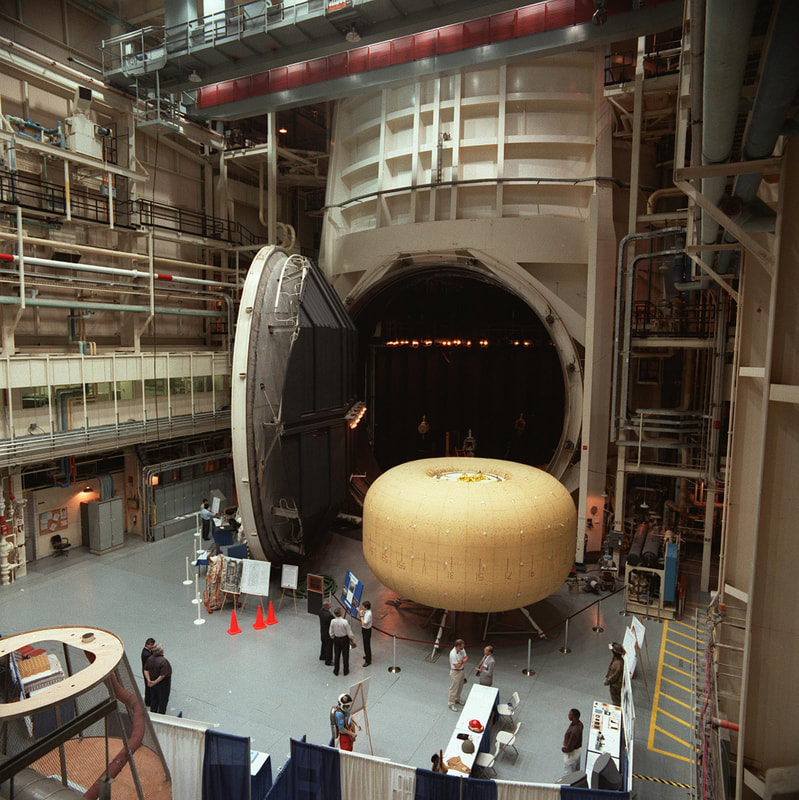

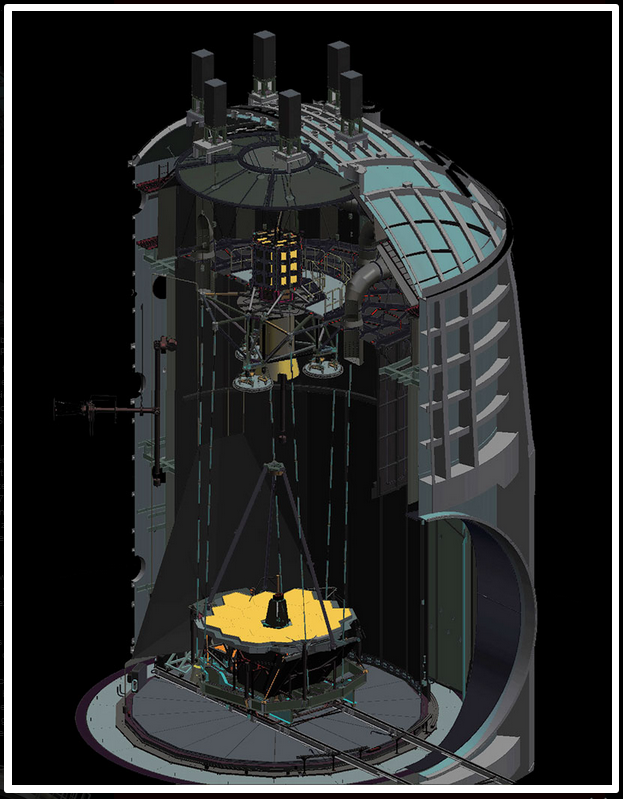

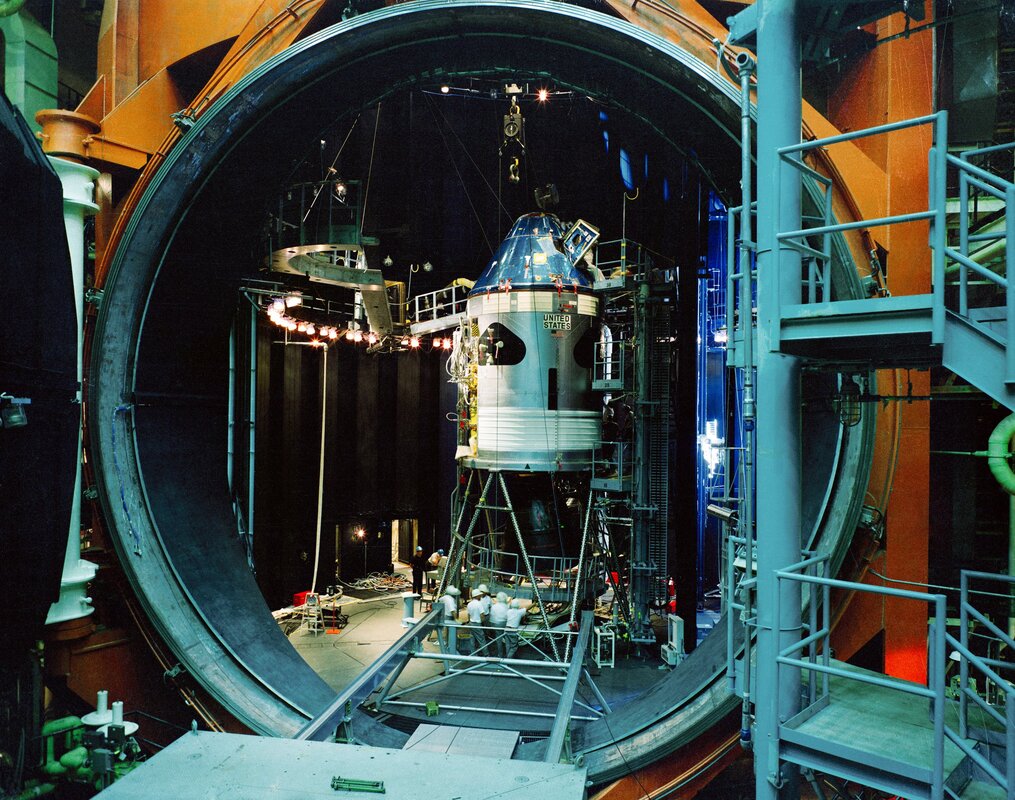

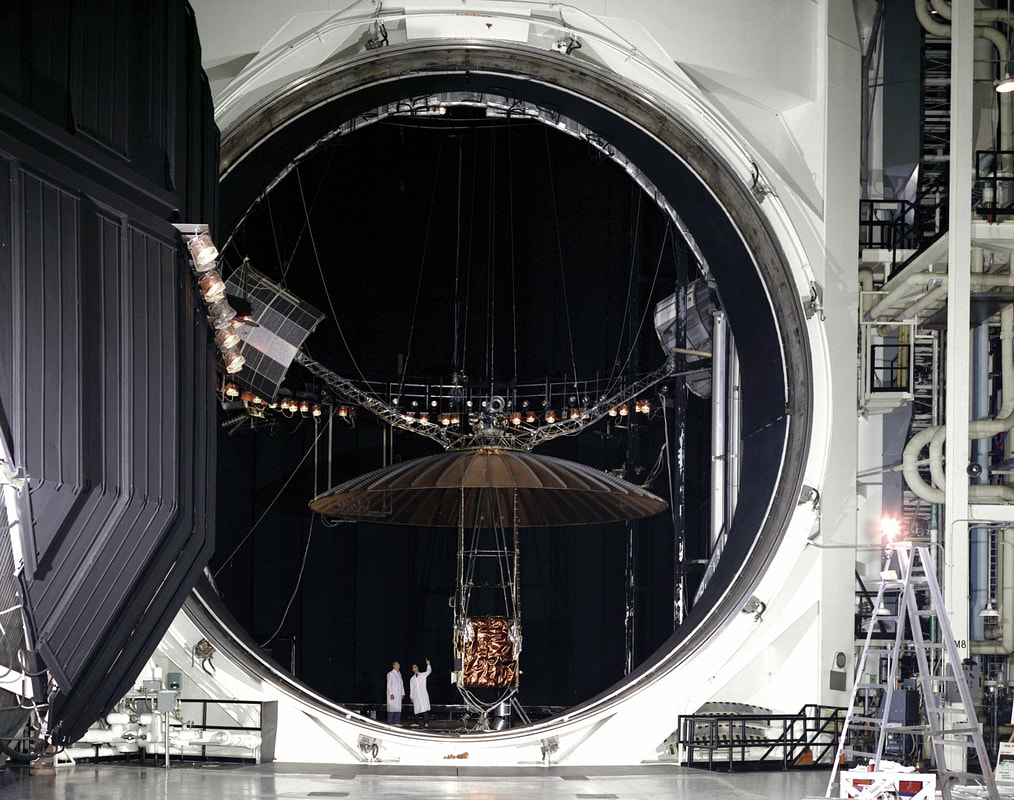

Space Environmental Simulation Laboratory, Johnson Space Center

Dr. Guzman was in the position of Electronic Technician and later as a Computer Specialist, responsible for helping maintain the mainframe computers and large data display rooms associated with the world's largest vacuum/space heat/space cold simulation facility. This involved providing real-time supporting for flights of the Apollo Telescope Mount(ATM) and Sky Lab. This facility features a 40 foot diameter door, a 40 foot diameter, and is a 5 story high vacuum chamber. It uses carbon-arc lighting to simulate the intense solar heat loading and cryogenic nitrogen panels to apply space freezing temperatures to the test article, which were usually space craft and satellites. This facility is kept at a 10K micron cleanliness level, similar of what is required for manufacturing today's electronic chips. This contract electronic specialist position was part of General Electric Space Division.The facility was featured in the making of the movie, The China Syndrome, with Jane Fonda and Micheal Douglas.

Dr. Guzman was in the position of Electronic Technician and later as a Computer Specialist, responsible for helping maintain the mainframe computers and large data display rooms associated with the world's largest vacuum/space heat/space cold simulation facility. This involved providing real-time supporting for flights of the Apollo Telescope Mount(ATM) and Sky Lab. This facility features a 40 foot diameter door, a 40 foot diameter, and is a 5 story high vacuum chamber. It uses carbon-arc lighting to simulate the intense solar heat loading and cryogenic nitrogen panels to apply space freezing temperatures to the test article, which were usually space craft and satellites. This facility is kept at a 10K micron cleanliness level, similar of what is required for manufacturing today's electronic chips. This contract electronic specialist position was part of General Electric Space Division.The facility was featured in the making of the movie, The China Syndrome, with Jane Fonda and Micheal Douglas.

Sky Lab and Apollo Telescope Mount(ATM)

1004 W. MacDade Boulevard Milmont Park, PA 19033

Monday Wednesday Saturday 10AM til 7PM

Monday Wednesday Saturday 10AM til 7PM